Price of photovoltaic panels at the source factory

How Much Do Industrial Solar Panels Cost?

Commercial solar panels typically cost about $325,000, with average costs in the US ranging between $50,000 and $600,000. Also, remember that the larger your commercial solar power

Solar Panel Manufacturing Cost: A Complete Factory

Starting a solar panel factory? Get a detailed cost breakdown for machinery, buildings, and working capital for 25 MW, 100 MW, and 800 MW

Solar Panel Manufacturing Cost: A Complete Factory Breakdown

Starting a solar panel factory? Get a detailed cost breakdown for machinery, buildings, and working capital for 25 MW, 100 MW, and 800 MW production lines.

How much is the factory price of solar energy

How much is the factory price of solar energy 1. The factory price of solar energy can vary significantly, influenced by several factors such as the

How Much Does Solar Panels Cost in Singapore? (2025)

Discover the complete breakdown of solar panel costs in Singapore, including the average prices for panels, inverters, installation, and miscellaneous costs.

Solar Manufacturing Cost Analysis | Solar Market

Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers. This

Monthly Solar Photovoltaic Module Shipments Report

Table 6. Source and disposition of photovoltaic module shipments U.S. shipments and sales to the original equipment manufacturer (OEM) for resale and export shipments are not published

How to Source Solar Panels Directly from Manufacturers in 2025

Compare global solar panel prices and learn how to negotiate directly with manufacturers. Practical advice for businesses seeking to optimize solar investments.

Solar Industry Research Data – SEIA

Solar energy in the United States is booming. Along with our partners at Wood Mackenzie Power & Renewables, SEIA tracks trends and trajectories in the

How Much Does it Cost to Produce Solar Panels and Modules

To shield solar cells from environmental factors and safeguard their delicate nature, they are encapsulated with a protective layer of ethylene vinyl acetate. The price of

China solar panel manufacturers seek government action to halt

Chinese solar panel manufacturers said they are seeking immediate government intervention to curb investment and industry collaboration to arrest a plunge in prices of solar

Cost Guide To Installing A Solar Panel In Malaysia

Below is a table by TNB showing the suggested solar PV size for households with differing electricity bills. Source Another thing to consider

Solar (photovoltaic) panel prices

IRENA presents solar photovoltaic module prices for a number of different technologies. Here we use the average yearly price for technologies ''Thin film a-Si/u-Si or

How Much Do Industrial Solar Panels Cost?

Commercial solar panels typically cost about $325,000, with average costs in the US ranging between $50,000 and $600,000. Also, remember that the larger

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers. This approach enables NREL to

How much does the factory solar panel cost? | NenPower

Looking ahead, future trends indicate ongoing reductions in solar panel pricing. As technology continues to advance and efficiency rates rise, the production costs are expected

Global PV Module Market Analysis and 2025 Outlook

PV modules are the central component of the solar industry. This analysis reviews market conditions that affect solar panel pricing and availability.

Cost Breakdown of a Solar Panel: From Manufacturing to Market

Navigating the intricacies of the solar panel market requires a keen understanding of the various cost factors detailed in this article. At SolarCtrl, we are committed to leveraging

Solar Panel Installation Philippines for 3kw, 5kw, 10kw

Pricing Source Google Search Here Are The Influencing factors The investment costs of a solar panel installation in the Philippines are not

6 FAQs about [Price of photovoltaic panels at the source factory]

Where did photovoltaic cost data come from?

Photovoltaic cost data between 1975 and 2003 has been taken from Nemet (2009), between 2004 and 2009 from Farmer & Lafond (2016), and since 2010 from IRENA. Prices from Nemet (2009) and Farmer & Lafond (2016) have been converted to 2024 US$ using the US GDP deflator, to account for the effects of inflation.

How much money do you need to produce solar panels?

To ensure you have enough stock to avoid stopping production due to a lack of materials, you should estimate approximately €6.5 million for working capital, including materials in stock. The cost of materials for solar panels constitutes over 95% of the total production costs, making it the dominant factor in solar module production.

How do market factors affect the cost of solar panels?

The impact of market factors on the cost of solar panels is nuanced, influenced by supply and demand dynamics, technological advancements, and the competitive landscape. These elements collectively dictate the pricing strategies of manufacturers and ultimately the affordability of solar technology for consumers.

How are PV production costs modeled?

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

Why are solar panels so expensive?

Tariffs, import duties, and taxes can either protect local manufacturers or make imported solar panels more expensive. For example: Import Tariffs: Many countries impose tariffs on imported solar panels to protect domestic industries from foreign competition. These tariffs can significantly increase the cost for consumers in the importing country.

Which solar panels are the most expensive?

Monocrystalline solar panels are the most expensive due to their higher efficiency and sleek look. Polycrystalline panels are less efficient and cheaper, while thin-film panels, although aesthetically pleasing, have the lowest efficiency and lifespan, making them the least expensive to manufacture.

Related information

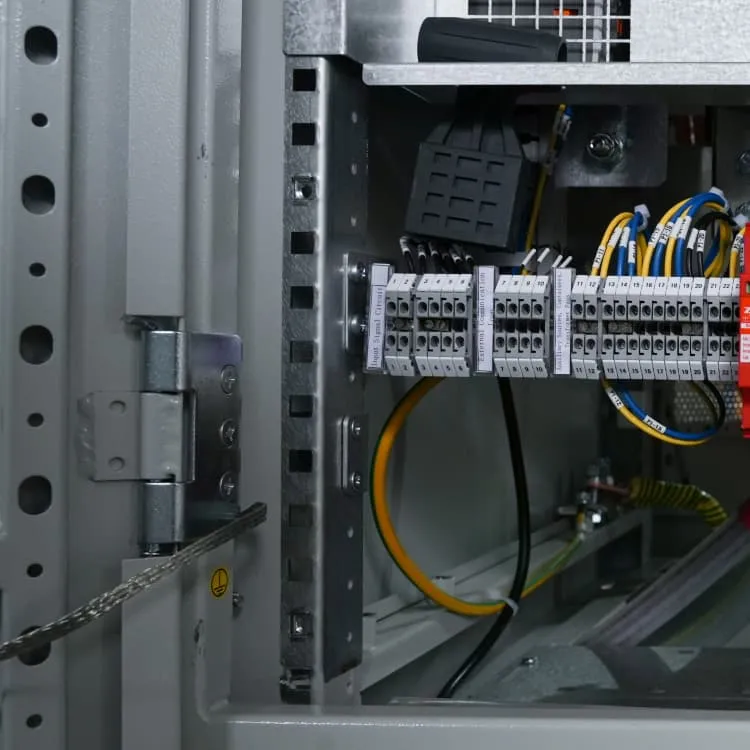

- Tunisia Battery Replacement Cabinet Platform

- Solar power generation for home use retail and wholesale

- Huawei s energy storage projects under construction in ASEAN

- Battery energy storage investment costs

- Energy storage cabinet manufacturer container

- What are the large-scale energy storage cabinets for

- A photovoltaic panel that generates two kilowatt-hours of electricity a day

- How many kilowatts can a 24v inverter produce at most

- Solar Outdoor Portable Power Bank

- Nicaragua pack lithium battery

- San Marino ESS photovoltaic home energy storage system

- Seismic design of communication base station inverter

- Chassis Portable Power Supply

- Norway outdoor power wholesale

- Egypt monocrystalline photovoltaic module panels

- How many volts does an inverter use for solar panels

- New energy storage power supply OEM

- Manufacture high frequency inverter 12V to 220V

- How many photovoltaic panels should be installed for home use

- Huawei Spain Microinverter Call

- Where to buy solar photovoltaic panels in Chad

- Photovoltaic off-grid system composition

- Advantages and Disadvantages of Solar Energy Storage Integrated Charging Stations