New energy battery cabinet heat dissipation aluminum plate

Improving Heat Dissipation in Battery Modules with Custom Plates

In this article, we will explore the latest advancements and techniques in the development of custom plates for improved heat dissipation in battery modules, focusing on their design,

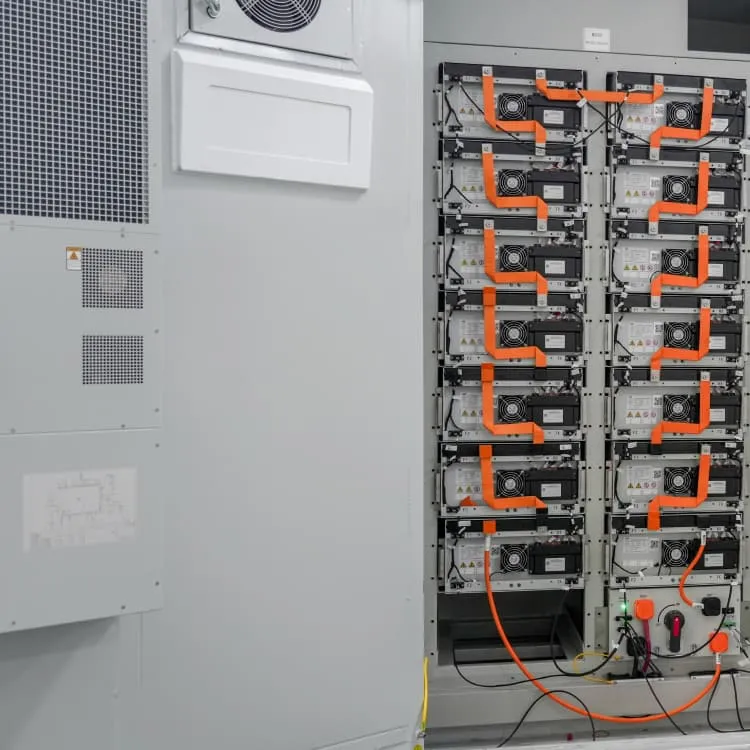

New energy battery cabinet modification and heat dissipation

Does guide plate influence air cooling heat dissipation of lithium-ion batteries? Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen

Aluminum liquid cold plates: the core of heat dissipation in new

Aluminum liquid cold plates have become a mainstream choice for cooling power batteries in new energy vehicles. Leveraging aluminum''s excellent thermal conductivity (reaching 160-200W/

Materials Innovation in Thermal Management: Advancing

These advancements are crucial for the effective dissipation of heat and the ability to withstand the mechanical stresses associated with larger and more powerful batteries. The

Optimized Design Solutions for Battery and Frame

Among the various components influencing new energy vehicles, the battery and frame play particularly prominent roles. Summarizing recent advancements in the optimized design of

Working principle of heat dissipation of new energy battery

This paper investigates the heat generation and heat dissipation performance of a battery pack based on the normal heat generation and thermal runaway mechanism Multiphysics simulation

Battery cabinet heat dissipation

A thermal management system for an energy storage battery The results show that the heat dissipation effect of optimized solution 4 is significantly better than other solutions, and its

New Energy Battery Packing Aluminum Cold Plate

In order to pursue high-efficiency, low-noise and low-temperature operation, and when space is limited, heat dissipation becomes the biggest limit to the idealization of product development,

Improving Heat Dissipation in Battery Modules with Custom

In this article, we will explore the latest advancements and techniques in the development of custom plates for improved heat dissipation in battery modules, focusing on their design,

How to calculate the heat dissipated by a battery pack?

I have a battery pack consisting of 720 cells. I want to calculate the heat generated by it. The current of the pack is 345Ah and the pack voltage is 44.4Volts. Each cell has a

New Energy Vehicle Power Battery Aluminum Material

The power battery cover plate produced by Chalco generally uses 3003-H14 aluminum plate. 3003 belongs to aluminum manganese alloy, with the main

Heat Sinks for EV Battery Cooling

This page brings together solutions from recent research—including microfin heat sink designs, dual-layer thermal management systems, integrated housing-based heat

Power Battery Pack Aluminum Water Cooling Plate

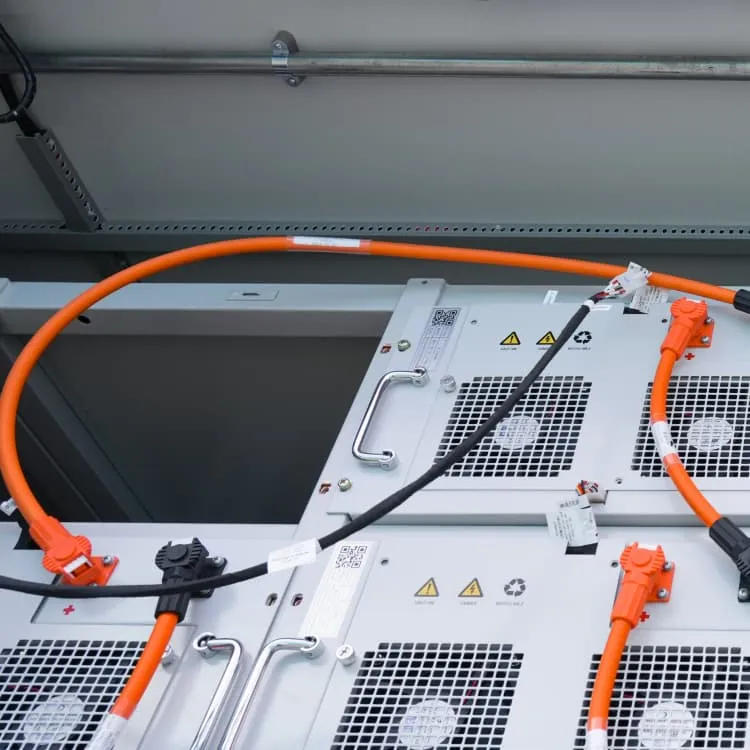

The battery core is transferred to the power battery pack aluminum water cooling plate through the thermal conductive silica gel sheet. The heat is carried way

New energy vehicle battery heat sink

New Energy Vehicle Battery Heat Sink Advanced thermal management solutions for electric vehicle batteries. IGSINK delivers high-performance heat sinks, cooling plates, and thermal

Improving Heat Dissipation in Battery Modules with Custom Plates

Material Selection for Custom Plates The selection of materials for custom plates in battery modules is a critical factor influencing the performance and efficiency of battery systems.

What are the types of cold plates used in the new energy sector?

The key to the application of liquid cooling plates in the new energy field is to improve the thermal management efficiency of the system. I believe this article can help you understand what kind

A topology optimization-based-novel design and

The effects of coolant flow rate, battery discharge rate, and cooling plate thickness and quantity on the heat dissipation performance of the liquid cooling system were

New Energy Vehicle Power Battery Aluminum Material

The power battery cover plate produced by Chalco generally uses 3003-H14 aluminum plate. 3003 belongs to aluminum manganese alloy, with the main alloy element being manganese,

What are the types of cold plates used in the new

The key to the application of liquid cooling plates in the new energy field is to improve the thermal management efficiency of the system. I believe this article

A new design of cooling plate for liquid-cooled battery thermal

This paper presents a new design of a prismatic battery cooling plate with variable heat transfer path, called VHTP cooling plate. The grooves on the VHTP layer are utilized to

Heat dissipation design of new energy battery cabinet

Learn how advanced battery technologies and energy management systems are transforming renewable energy infrastructure. Heat dissipation design of new energy battery cabinet

New Energy Battery Cabinet Heat Dissipation Design Solution

heat dissipation structure of vehicle mounted energy storage batteries. The current research status of NSGA-II both domestically and internationally is analyzed. The second part proposes

How does the energy storage battery cabinet dissipate heat?

By utilizing a greater surface area, passive heat sinks can effectively radiate excess heat into the surrounding environment. This technique aids in distributing temperature evenly

Multi-scale modelling of battery cooling systems for grid frequency

The introduction of battery energy storage systems is crucial for addressing the challenges associated with reduced grid stability that arise from the large-scale integration of

New energy battery cabinet modification and heat dissipation

The integration of advanced heat dissipation technologies, such as heat pipe cooling plates, remote heat transfer heat pipes, and liquid-cooled cold plates, presents a promising solution

3003 Aluminum Plate for New Energy Automobile Lithium Battery

3003 aluminum plate is a high-quality aluminum-manganese alloy, which is widely recognized for its excellent corrosion resistance, light weight and superior forming performance.

New Energy Battery Packing Aluminum Cold Plate

In order to pursue high-efficiency, low-noise and low-temperature operation, and when space is limited, heat dissipation becomes the biggest limit to the

Aluminum liquid cold plates: the core of heat dissipation in new energy

Aluminum liquid cold plates have become a mainstream choice for cooling power batteries in new energy vehicles. Leveraging aluminum''s excellent thermal conductivity (reaching 160-200W/

Materials Innovation in Thermal Management: Advancing Aluminum

These advancements are crucial for the effective dissipation of heat and the ability to withstand the mechanical stresses associated with larger and more powerful batteries. The

6 FAQs about [New energy battery cabinet heat dissipation aluminum plate]

Which cooling plates are best for prismatic batteries?

For prismatic batteries, 73.3% of customers opt for liquid cooling plates with bottom heat exchange. Increasingly, many are now also using side heat exchange or multi-sided heat exchange. Side heat exchange involves extruding micro-channel tubes and bending them, similar to serpentine tubes.

What material is used in power battery aluminum trays?

Chalco's production of power battery aluminum trays mostly uses 6-series 6061 aluminum plate as the raw material for battery aluminum trays, which can meet the characteristics of high precision, corrosion resistance, high temperature resistance, and impact resistance to protect the battery core.

Can liquid cooling plates be used in the new energy field?

The key to the application of liquid cooling plates in the new energy field is to improve the thermal management efficiency of the system. I believe this article can help you understand what kind of liquid cooling plates you can choose to meet your project needs.

What kind of heat exchange solution do you use for a battery?

For cylindrical batteries, almost all customers use the side heat exchange solution with serpentine tubes, like the Tesla cylindrical battery heat exchange case. (serpentine tubes instructures) For prismatic batteries, 73.3% of customers opt for liquid cooling plates with bottom heat exchange.

What are the types of cold plates used in the new energy field?

So, what are the primary types of cold plates used in the new energy field? In practical mass production projects, an impressive 93.7% use key types of liquid cooling plates, including Hydroformed Cooling Plates, Extruded Cooling Plates, FSW (Friction Stir Welding) Cooling Plates, and Machined Cooling Plates.

What is a power battery casing made of?

The material of the power battery casing is generally made of aluminum casing, because the aluminum casing has excellent lightweight structure, good thermal conductivity, and is safer and more durable.

Related information

- Bulk solar panels in containers

- Lead energy storage battery

- Energy storage battery market in a year

- What is the maximum power of solar energy in watts

- 5G base station power consumption planning

- Practical home solar all-in-one machine

- Can a 12v battery be used as an inverter

- Nicaragua 18kw high quality inverter merchant

- Senegal wind power energy storage configuration

- Russian solar panel intelligent manufacturing

- Middle East Group Energy Storage Project

- Folding Solar Photovoltaic Panel 100W12v

- Which energy storage container is best in Arab countries

- Outdoor power supplies of different brands

- How to check the battery of communication base station EMS

- Equatorial Guinea nickel-cadmium battery energy storage container

- Indoor base station power supply solution

- What are the batteries for communication base stations in Uruguay

- Huawei energy storage projects and construction

- Iraqi energy storage fire protection system manufacturer

- Campsite Solar System

- Energy storage battery cabinet by site cabinet

- Monocrystalline silicon double-sided double-glass photovoltaic modules