Yaounde lithium battery BMS standard

(PDF) Review of Battery Management Systems (BMS

Additionally, current related standards and codes related to BMS are also reviewed. The report investigates BMS safety aspects, battery technology, regulation needs, and offer...

The Role of the BMS in Modern Lithium Batteries –

Modern lithium batteries are no longer simple storage units; they are intelligent energy systems designed to deliver safe, efficient, and lasting

The Importance of Battery Management Systems for Lithium

Learn why a Battery Management System (BMS) is essential for the safety and efficiency of lithium batteries, including LiFePO4 and Lithium Polymer types.

Comprehensive review of battery management systems for

Research into lithium-ion battery technologies for Electric Vehicles (EVs) is advancing rapidly to support decarbonization and mitigate climate change. A critical aspect in ensuring the

What Amp BMS Do I Need? Sizing Battery Management Systems

Consider some of the top recommended BMS options available on the market today. Whether you have lithium-ion batteries, lead-acid batteries, or other specialized battery types like LiFePO4

Guide to Battery Safety Standards in India – compiled by ARAI

These amendments include additional safety requirements related to battery cells, BMS, on-board charger, design of battery pack, thermal propagation due to internal cell short

Functional and Safety Guide for Battery Management System (BMS

Battery Support Systems (e.g. fire extinguisher). Loss of BSS / BMS safety function The purpose of this test is to ensure that any BMS safety function failure (e.g freezed sensor value) is

D6.7 – Battery Management System Standard

The existing standard applicable for testing overvoltage and undervoltage protection functionality of a BMS, is ISO 12405-2 - Electrically propelled road vehicles -Test specification for lithium

The current situation of lithium batteries in Yaounde

Yaounde lithium battery is most in need of materials. With a focus on next-generation lithium ion and lithium metal batteries, we briefly review challenges and opportunities in scaling up lithium

Understanding the Role of the BMS in Modern Lithium Batteries

Understanding the Role of the BMS in Modern Lithium Batteries Modern lithium batteries are more than just rows of chemical cells—they''re smart energy systems, and the Battery Management

saracho

The lithium-ion battery industry''''s value chain is a complex process that involves the sourcing of raw materials, the manufacturing of battery components, and the assembly of final products.

BMS for Lithium-Ion Battery: Essential Guide

Discover the crucial role of a BMS for lithium-ion batteries in ensuring safety, performance, and longevity. Learn about standard vs smart BMS options.

BMS for lithium batteries: Optimized performance

Lithium-ion batteries are at the heart of modern technology, used in electric vehicles, electronic devices and energy storage systems. To fully

LITHIUM BATTERY丨BATTERY MANAGEMENT SYSTEM BMS

Which BMS is best for my lithium-ion battery? The safety of your batteries is paramount at BMS PowerSafe. Whatever their electrochemistry (Lithium-ion, Ni-MH, Sodium-ion etc), we develop

Limitation du courant de charge de la batterie au lithium de Yaoundé

La charge de batteries au lithium présente statistiquement le plus grand risque d''''incendie. C''''est notamment le cas lorsqu''''une batterie lithium défectueuse est connectée à un chargeur et que

IEC publishes standard on battery safety and performance

IEC 62619 specifies requirements and tests for the safe production of secondary lithium cells and batteries used in industrial application.

Battery Management System BMS for Lithium-Ion

What is BMS for Lithium-Battery Pack In the lithium-ion battery pack, there are the main electronic modules: the batteries (cells) connected in

BMS for lithium batteries: Optimized performance

Lithium-ion batteries are at the heart of modern technology, used in electric vehicles, electronic devices and energy storage systems. To fully exploit their potential, while

Safety Standards For Battery Management (BMS) In Electric Vehicle

In this article, I will discuss the types of safety standards for battery management systems (BMS) in electric vehicles and how they affect.

The Importance of Battery Management Systems for Lithium Batteries

Learn why a Battery Management System (BMS) is essential for the safety and efficiency of lithium batteries, including LiFePO4 and Lithium Polymer types.

6 FAQs about [Yaounde lithium battery BMS standard]

What are functional safety standards for battery management systems (BMS)?

Functional safety standards ensure that safety-related functionality in Battery Management Systems (BMS) is maintained throughout its lifecycle, mitigating risks that could compromise the system’s reliability and safety. ISO 26262 is a key standard for automotive functional safety, focusing on electrical and electronic systems, including BMS.

Does BMS work in a safety battery support system?

operational. BMS active charge control function is inhibited during this process, and BMS the main contactors. In addition, cell overheating with an inhibited battery pack cooling control function should be secured. The objective is to validate the BMS functionality of start-up of safety battery support systems (e.g., fire extinguisher).

What are the benefits of a battery management system (BMS)?

The operational benefits include safety, reliability, and dual-purpose. BMS minimizes the occurrence of a thermal runaway for high-voltage batteries. BMS also identifies the faulty cells connected in series and parallel (dual-purpose). The economic advantages of BMS are extensions of battery lifetime and lowering the cost.

What are the hazards associated with BMS operation within battery systems?

T able 3presents the potential hazards related to BMS operation within battery systems. T able 3. Operational BMS hazards. 1. Loss of air conditioning and battery cooling (BSS—battery support system). 2. Loss of battery heating controls (BSS). 3. Loss of battery voltage control function (BMS/EMS). 4.

Why should chemical containment systems be included in a BMS?

Chemical containment systems must be incorporated into the BMS to prevent leaks or spills of hazardous materials such as lithium or electrolyte. Safety protocols include protective measures to ensure safe battery disposal, recycling, and transportation to minimize environmental impact.

How to check if a battery pack is compatible with a BMS?

Finally, BMS developers should consult magnetic compatibility. They can be summarized as listed below: 1- Protect the battery pack. 2- Monitor the battery pack state. 3- Measure battery cell and pack voltage. 4- Measure battery cell and pack temperatur e. 5- Measure battery pack curr ent flow. 6- Detect battery system leakage currents.

Related information

- Albanian energy storage lithium iron phosphate battery

- Electricity prices for energy storage products

- Advantages and Disadvantages of Hybrid Energy Storage Vanadium Batteries

- The safety of battery energy storage power generation

- Seychelles home solar photovoltaic panels

- Does Trinidad and Tobago have liquid-cooled energy storage containers

- Solar panel factory sales

- Price of Paraguayan public transport mobile energy storage vehicle

- 12v 1000W Huawei inverter price

- Price of 250wp photovoltaic modules

- 12v inverter or 72v inverter is better

- Brand new photovoltaic panels selling price

- Rural rooftop photovoltaic panel design

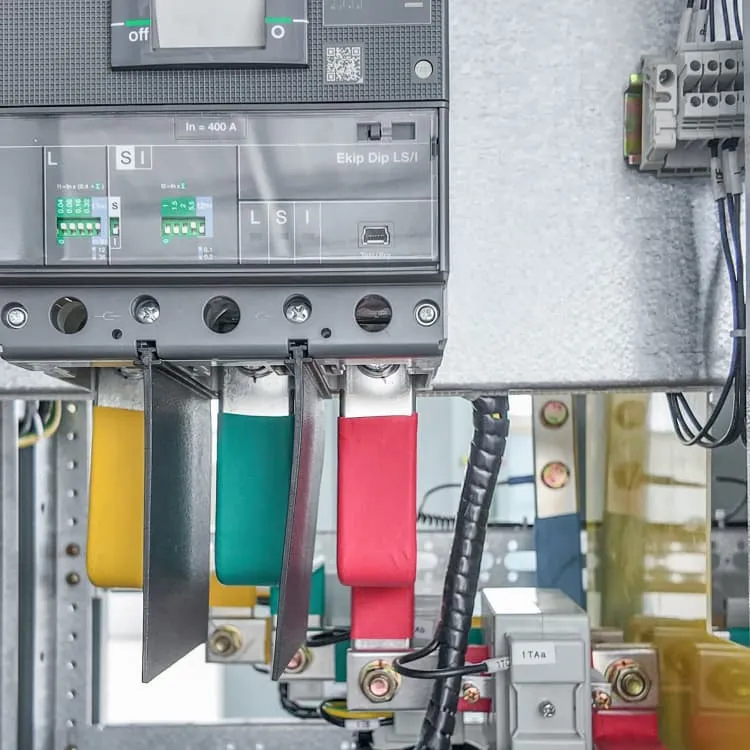

- Electric energy storage cabinet development

- Average electricity generation from photovoltaic panels in Norway

- How much does a 170 000 watt energy storage cabinet cost

- Chad BESS outdoor base station power supply

- Huawei 1kW inverter

- Polish photovoltaic solar panel company

- What are the battery container companies in the Philippines

- Solar panels conduct electricity

- Somaliland Energy Storage Distribution

- Photovoltaic Energy Storage Systems in Belarus