Pack battery control plan

Safe, Fast and Reproducible Testing of Battery

The Battery Management Systems (BMS) The electrification of road vehicles and many modern concepts for stationary energy storage rely on the use of lithium

Battery Packs, Stack, and Modules

In this 3 part series, Nuvation Energy CEO Michael Worry and two of our Senior Hardware Designers share our experience in energy storage system design from the vantage point of the

Lithium Ion Battery

1.0 PURPOSE The intent of this guideline is to provide users of lithium-ion (Li-ion) and lithium polymer (LiPo) cells and battery packs with enough information to safety handle them under

Battery Packaging Architectures: Materials Considerations

Challenges surrounding battery packaging architecture include dealing with packaging space, thermal management, and optimizing battery-management systems.

The Fundamentals of Battery/Module Pack Test

Before we discuss how to select the right battery test equipment for a given application, certain key challenges and fundamental concepts of battery testing will be reviewed. This application

How to Build Your Own Battery Pack

Building your own battery pack is a rewarding project that allows you to create a customized power source for various devices, from electric vehicles to solar setups. Whether

An Exhaustive Guide To Building 18650 Packs

Fortunately [Adam Bender] is on hand with an extremely comprehensive two-part guide to designing and building lithium-ion battery packs from cylindrical 18650 cells.

Battery Pack Designer''s Guide: From Beginner to Pro [With

Key Takeaways Master the fundamentals of battery pack design to create efficient, safe, and application-specific energy storage solutions that meet modern performance demands. Start

BATTERY CELL, MODULE & PACK TESTING

For Battery Cells, Modules & Packs The types of testing required will vary depending on whether you''re testing the chemistry of a stand-alone component (cell) or the e. gineering of a whole

The Best USB Battery Pack for 2025: Buyer''s Guide

Are you looking for the best USB battery packs? Here are the top picks. And you''ll learn their advantages, and advice on how to select the correct one.

Pack Design

With the module design we look at Mechanical, Electrical, Thermal, Safety and Control. In pack design we repeat that approach. The mechanical integration and support of all sub-systems

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Custom Battery Packs: Testing and Quality Assurance Measures

Summary Quality assurance for battery packs is performed throughout the entire life of the cells: from the battery manufacturer to the manufacturer''s customer and to the end

TSA battery rules: approved power banks & chargers

Traveling can eat away at the battery life of your phone, laptop or tablet. Make sure that you stay charged while on the road and in the air with

NGS Singer Star Duo

The system offers volume and echo control directly on the microphone and a real-time battery level indicator to avoid interruptions. With a 1500mAh battery in the microphones and a

The Fundamentals of Battery Pack and Module Testing

When configured as an EV battery cycler, it is designed for battery cycling (charging and discharging) of packs and/or modules and can provide fast and accurate control

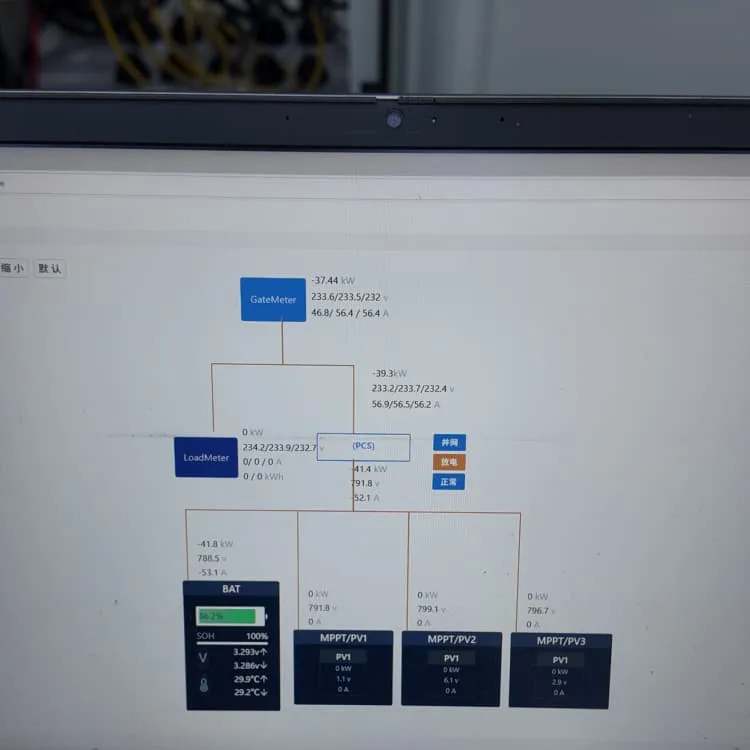

Arlington Battery Energy Storage System

An integrated Battery Management System (BMS) monitors key datapoints such as voltage, current, and state of charge (SOC) of battery cells, in addition to providing control of

ESS''s Battery Pack Design Checklist: Your Roadmap to Smarter Battery

Streamline your battery pack development with ESS''s Battery Pack Design Checklist. Learn how to integrate safety, reliability and performance into every subsystem from

Understanding the Circuit Diagram of a Battery Management

A well-designed battery management system circuit is essential for maximizing the performance, safety, and longevity of battery packs. It provides enhanced battery life, improved safety

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

The Fundamentals of Battery Pack and Module Testing

For Battery Cells, Modules & Packs The types of testing required will vary depending on whether you''re testing the chemistry of a stand-alone component (cell) or the e. gineering of a whole

Design, Optimization, and Analysis of Electric vehicle Battery

Choosing the right cooling mechanism for a lithium-ion battery pack for electric vehicles and developing an appropriate cooling control plan to maintain the heat contained within a safe

Related information

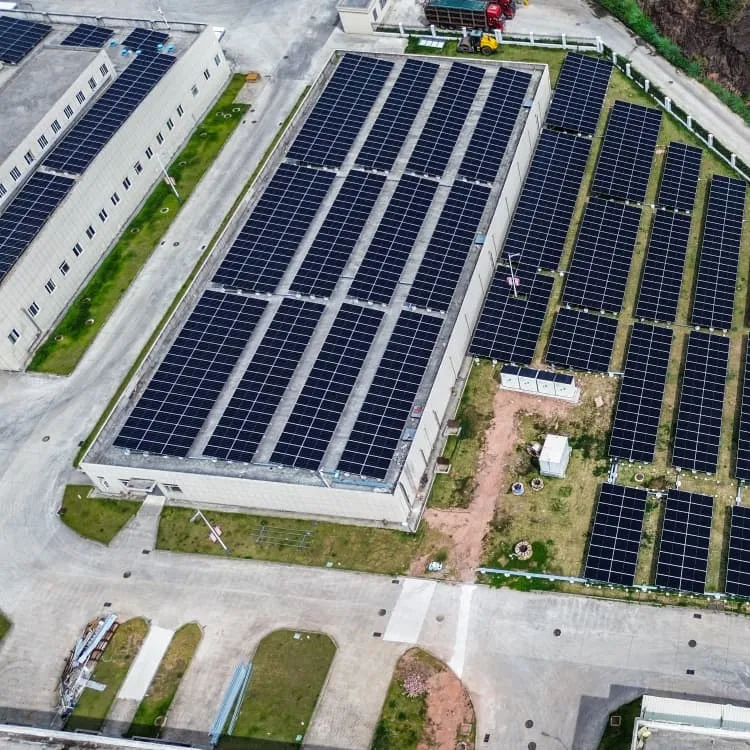

- Photovoltaic power generation efficiency of solar panels

- Qatar BIPV photovoltaic roof integrated panel installation

- Burkina Faso imports energy storage battery companies

- Mongolia New Energy Storage Equipment Manufacturer

- Lithuania Solar Power System

- Congo Brazzaville Communication Base Station Inverter Cabinet Factory

- Photovoltaic 200-degree energy storage

- Hungarian home energy storage battery BESS

- Micronesia Photovoltaic Inverter

- Solar automatic inverter

- Production of high-frequency outdoor power supplies

- Which professional design is responsible for the effectiveness of energy storage power stations

- What is the typical capacity of a new energy battery cabinet

- Belgian manufacturer of power storage systems

- North Korea inverter battery

- Photovoltaic array combiner box sales

- Energy storage solution for single-family villas

- PV power generation plus energy storage plus charging station

- The Spanish wind power system was built in

- Southeast Asia Communications Green Base Station Photovoltaic Power Generation

- Nigeria Lithium Battery Energy Storage Industrial Park

- Huawei Liberia Outdoor Power Supply

- Algeria Energy Storage Battery Procurement